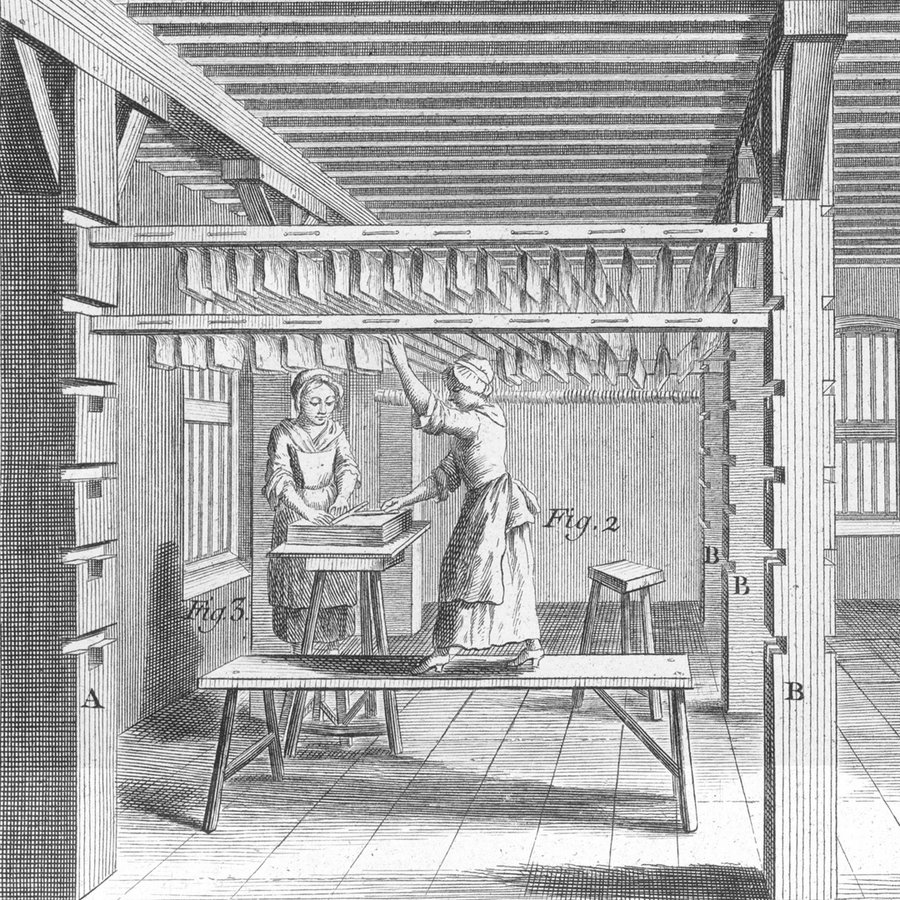

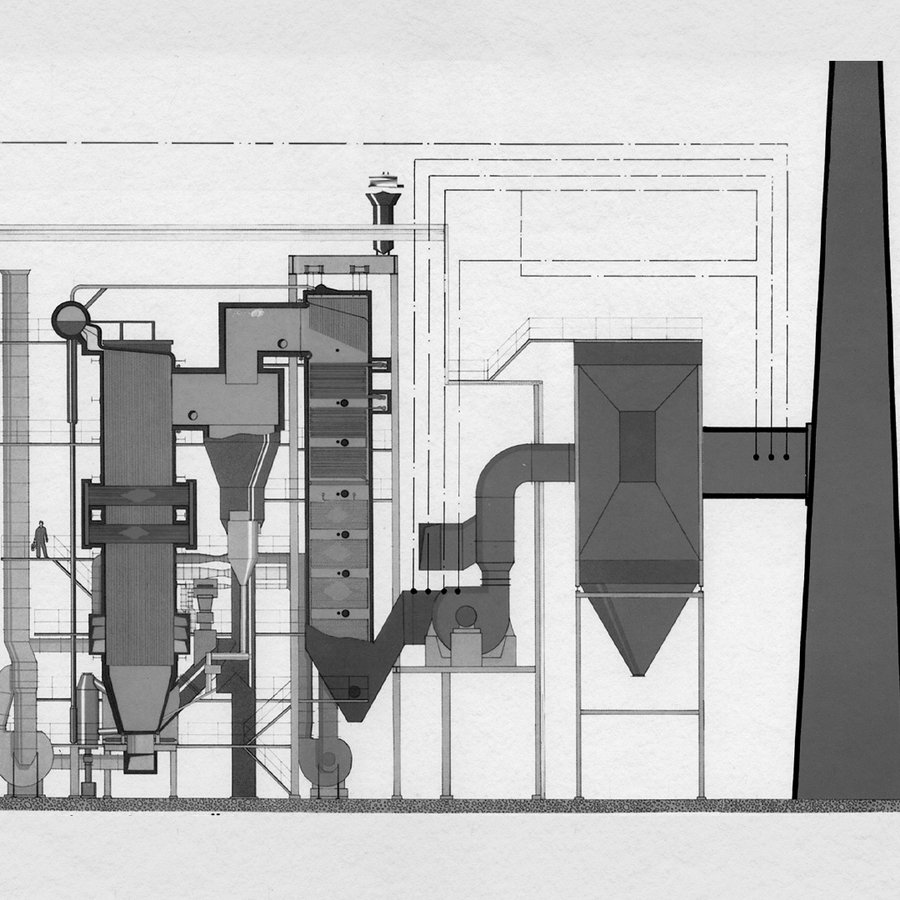

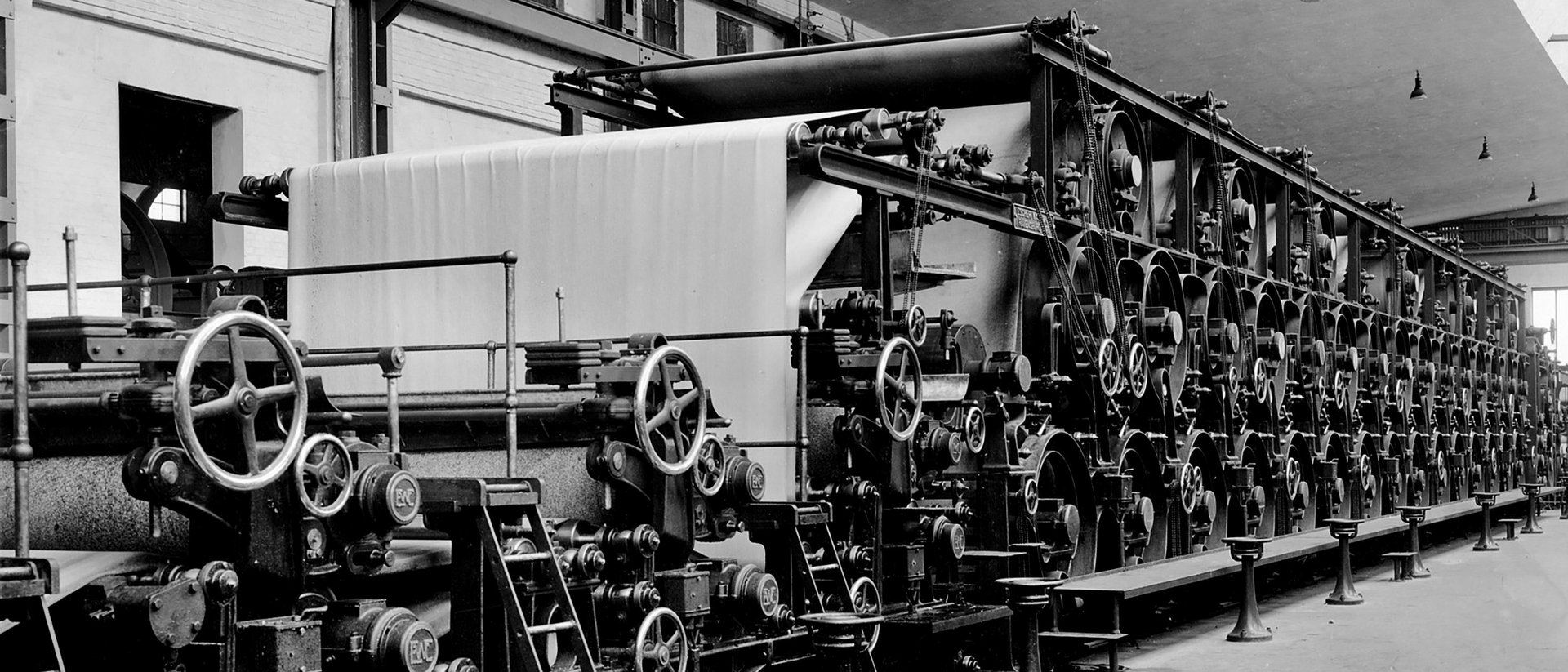

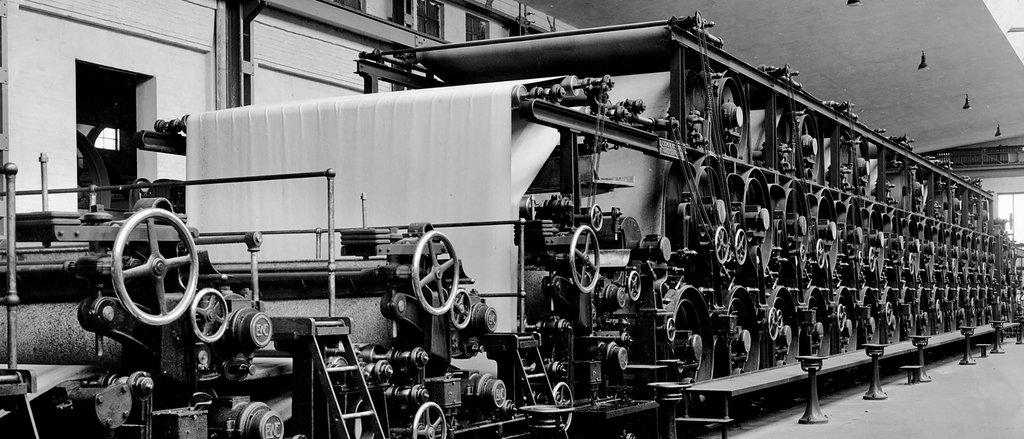

A mill on the Hase, a tributary of the river Ems. Rags that were turned into paper – this is how our company’s history begins in 1808. Back then, a resourceful papermaker from the city of Osnabrück, Gustav Wilhelm Quirll, sought out the exact same location for his mill that we now use to manufacture our specialty technical paper. The water power of the day was used to convert rags into a pulp, which was then turned into paper by means of a totally manual process. This was followed by the Industrial Revolution, wars, economic crises and changes of ownership – but the manufacture of paper just went on and on. Incidentally, the name KÄMMERER came into the equation in the year 1908, when the brothers Gustav and Rudolf Kämmerer bought the company and turned it into a manufacturer of paper products for the electrical industry.

“The past has shown us that we have always been capable of seeking out solutions for our problems and the task in hand. We have managed to withstand shortages of rags and water, times of war and economic downturns. But some things have remained constant: our team spirit and our identification with the company and its mission.”

Extracts from “200 Jahre Papiermacherei an der Hase” (2008)

![[Translate to Englisch:] Historie von KÄMMERER](/fileadmin/_processed_/9/c/csm_kaemmerer-historie-4_8b14255e62.jpg)